Wiring

Harnesses

Manufacturingis in our DNA

Cornelius Electronics has been engineering Wiring Harnesses for over 40 years. However, we’re so much more than just a manufacturer! We’re here to listen, process, advise and solve your supply and product problems.

Cornelius Electronics is founded on the inherent belief of TRUE working partnerships. With your vision and our expert technical department we will work together to prototype and engineer the perfect harness solutions for you.

With over 250 fully trained operatives we will bring your vision into production. From our 50,000 Sq Ft facilities we will deliver sustainable, controlled scalability. Supplying the harnesses you need, when you need them.

The product cycle doesn’t end with your delivery. What did we learn, what do you need next, how can we streamline your supply chain, how can we work together for sustained mutual growth? Strong partnerships, lasting connections.

Yes, we are a design, build and ship manufacturer… not just a brand. We have invested millions in our estate, plant, technology, systems and people to control and ensure we deliver on our quality, quantity and deadline promises.

Our privately owned facilities span over 50,000 Sq. Ft. and are driven by over 250 trained & experienced operatives. We are a flexible powerhouse of high mix, medium volume capacity with a UK and global wide client base.

Absolutely, we are committed to our industry and take great pride in our highly regarded reputation for service, methods and quality. To action our commitment, our certifications include ISO 9001, ISO 14001 & UL/CSA.

Established over 40 years ago and growing year on year, every decision we take contributes to our robust growth strategy. We believe in true partnerships, working closely with our clients to achieve mutual long term success.

With over £4m already invested in plant, systems & technology our production floors are a finely tuned hybrid of automated and hands-on production. We’re designed from the ground up to be competitive, why not find out by asking for a quote?

UL recognised components

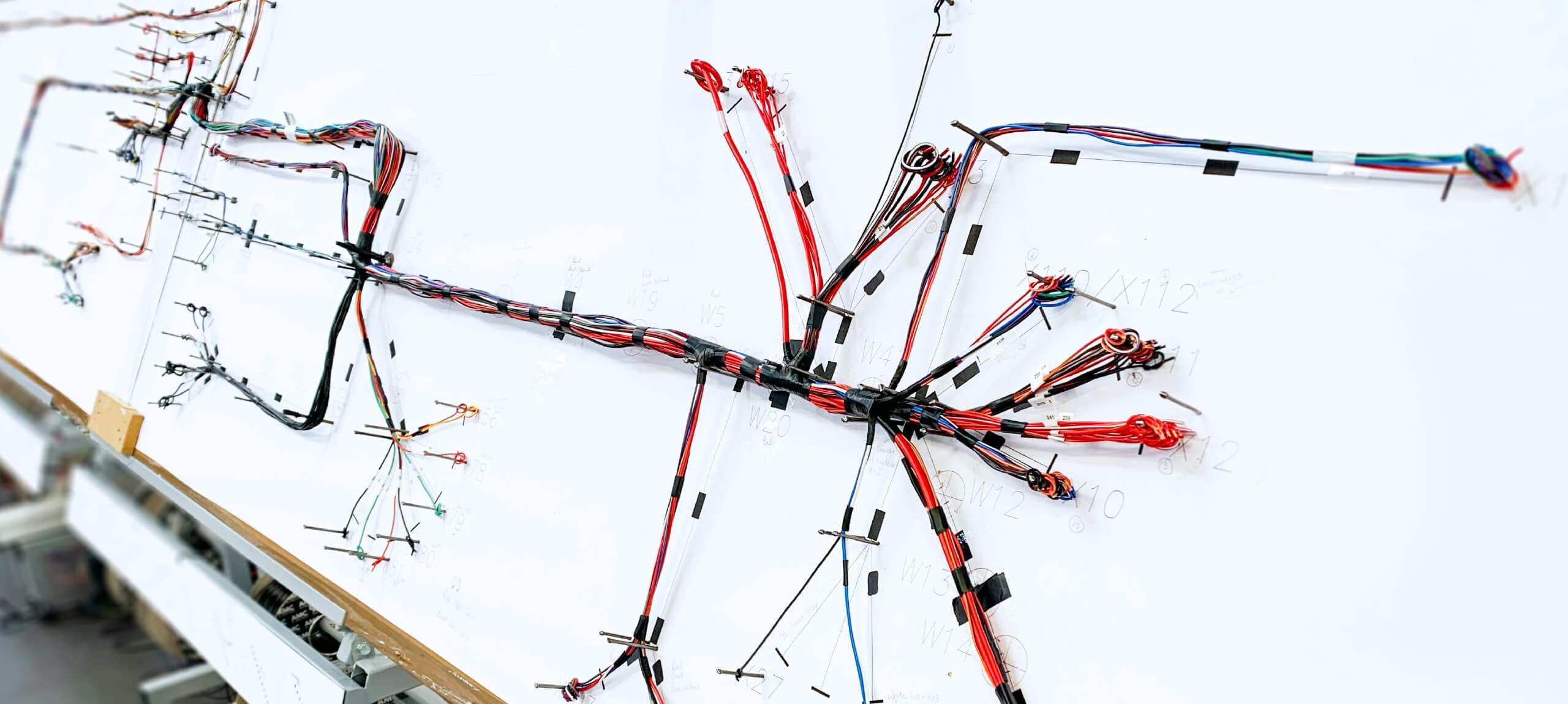

Cornelius Electronics has been manufacturing Wiring Harnesses for nearly half a century. What's more, we still lead the way... with Our 200+ strong team of operators trained in accordance with IPC, a fully dedicated and experienced in-house technical department a dedicated sales and support team all operating from our 50,000 Sq. Ft. operational facilities.

We are truly a relationship led brand, building strong connections for mutual growth. We service a variety of industries including transportation equipment, medical products, data centres, telecoms and industrial machinery. All of our Wiring Harness production services utilise the latest technologies.

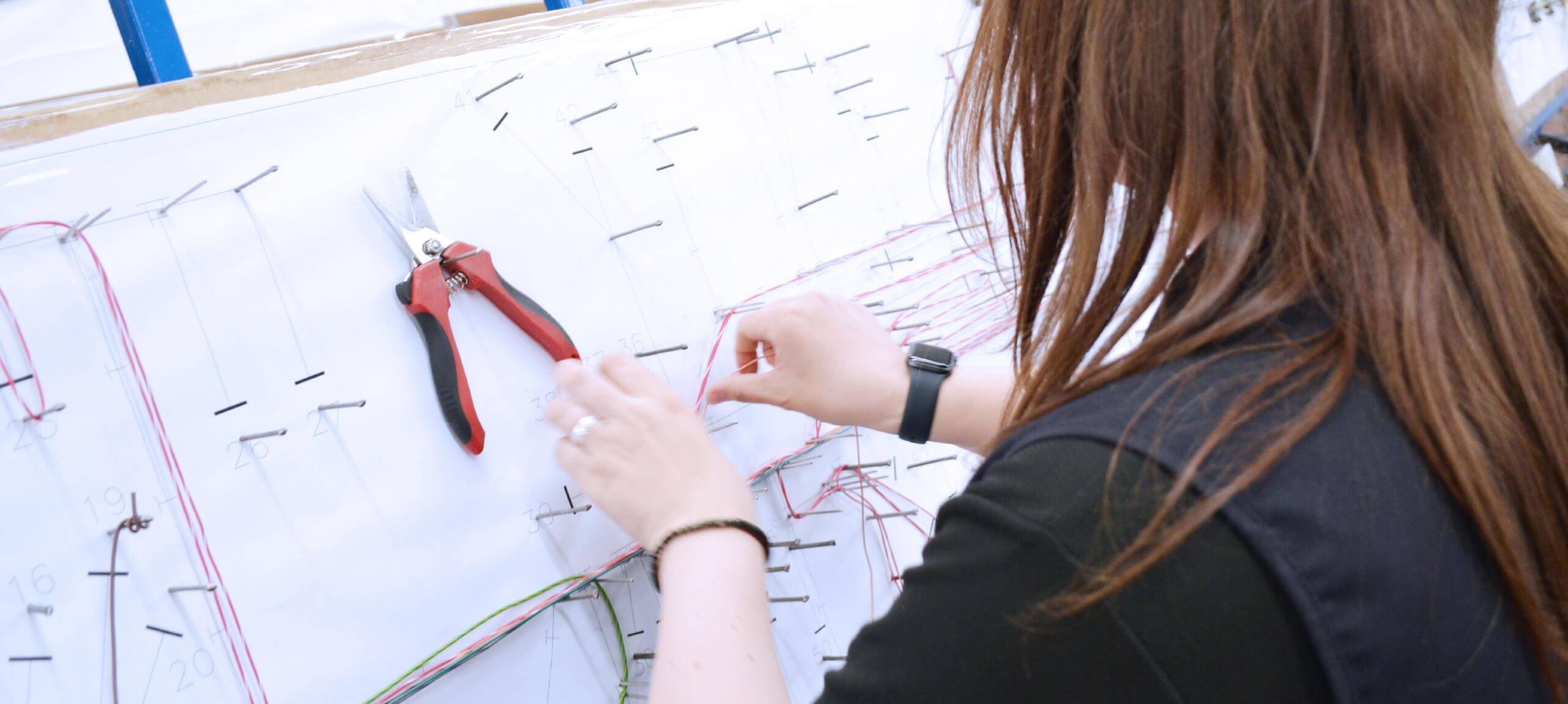

At Cornelius Electronics, manufacturing expertise is ingrained in our DNA, and our commitment to excellence is evident in every stage of the wiring harness building process. Firstly, clearly define the purpose of your wiring harness design. Delve into specific needs such as vibration resistance and environmental conditions to tailor the harness to your unique requirements. Moving forward, meticulous attention to specifications is crucial. Carefully choose wires and components based on electrical demands, environmental considerations, and mechanical properties.

Connectivity is a critical aspect. Select connectors that align with wire properties, accounting for circuit size, ease of joining, and insulation. Next, focus on routing. Plan wire routes strategically for accessibility, minimise electromagnetic interference risks, and segregate wires by function and voltage.

To safeguard against mechanical stress, incorporate strain-relief components and select appropriate materials. Leverage wiring harness design tools to generate accurate schematics, identifying potential issues and ensuring repeatable, controlled quality. Apply protective coverings based on environmental conditions and material properties.

Quality testing should be seamlessly integrated into the design process to assess electrical integrity, resistance, and connections. Comprehensive documentation, including schematic design and connector information, is vital for after-sales and service.

Finally, ensure compliance with regulatory and safety standards, tailoring your wire harness design to meet the specific requirements of your region or international markets. For an unparalleled level of expertise, trust Cornelius Electronics to harness the power needed for your project. Our skilled professionals are dedicated to delivering excellence in every wiring harness we build, making us the ideal partner for your next endeavour.

Wiring Harnesses are in our veins, partnerships are in our DNA. Connect with Cornelius Electronics Ltd today and discover how we can power-up your products and projects.

Our 250+ strong team include operators trained in accordance with IPC, a reliable and experienced technical department and a dedicated sales support team.

We may have been producing bespoke cable assemblies for nearly half a century, however we still pride ourselves on utilising the latest technology. To read more, click here >