In today’s competitive business landscape, companies are constantly seeking ways to optimize their operations, reduce costs, and improve efficiency. One area that often proves challenging for many companies is the cable assembly process. From the basics of cable assembly to the potential risks involved, this article will delve into the benefits of outsourcing this critical function.

Understanding Cable Assembly Process

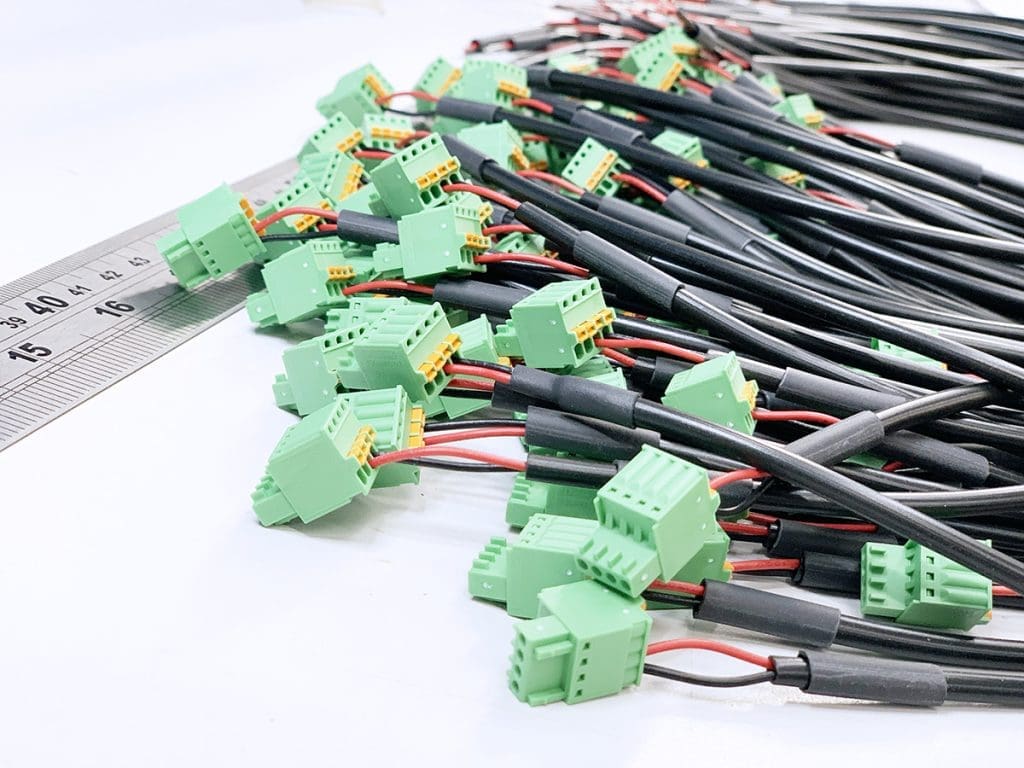

Before we explore the advantages of outsourcing cable assembly, it is essential to understand the intricacies of the process. Cable assembly involves the manufacturing and integration of various cables, connectors, and wires into a complete and functional unit. It requires expertise in areas such as wire harnessing, soldering, crimping, and quality assurance.

The Basics of Cable Assembly

Cable assembly involves several key steps, including cable cutting, stripping, and termination. It requires precise measurements, proper insulation, and the skillful handling of delicate components. A well-executed cable assembly ensures reliable connectivity and optimal performance in various industries, including automotive, aerospace, and telecommunications.

The Challenges in Cable Assembly

While cable assembly is crucial for the success of many businesses, it also poses its fair share of challenges. These challenges include high labor costs, complex processes, quality control issues, and difficulties in sourcing specialized equipment and personnel. These factors can hinder companies from achieving their full potential in terms of production efficiency and cost-effectiveness.

The Concept of Outsourcing in Cable Assembly

Outsourcing cable assembly has emerged as a viable solution for companies looking to streamline their operations and overcome the challenges mentioned earlier. But what does outsourcing mean in the context of cable assembly?

What Does Outsourcing Mean?

Outsourcing refers to the practice of delegating specific tasks or functions to external service providers. In the case of cable assembly, companies can partner with specialized contract manufacturers who have the expertise, resources, and experience to handle the entire cable assembly process.

The Role of Outsourcing in Cable Assembly

Outsourcing cable assembly allows companies to focus on their core business functions while entrusting the specialized task to professionals. It enables companies to tap into the extensive knowledge and capabilities of outsourcing partners, ultimately driving operational efficiency and cost savings.

The Advantages of Outsourcing Cable Assembly

Now that we have established the concept of outsourcing in cable assembly, let us delve into the numerous benefits it offers to businesses.

One of the primary advantages of outsourcing cable assembly is the potential for cost efficiency and savings. By partnering with a contract manufacturer, companies can avoid significant investments in equipment, infrastructure, and personnel. Additionally, outsourcing eliminates the need for companies to bear the overhead costs associated with maintaining an in-house cable assembly department.

Access to Specialized Skills and Technology

Outsourcing cable assembly gives companies access to the specialized skills and technology of contract manufacturers. These providers often have vast experience in cable assembly, ensuring high-quality outputs and compliance with industry standards. By leveraging the expertise of professionals, companies can achieve superior results and stay ahead of the competition.

Improved Focus on Core Business Functions

By entrusting cable assembly to a reliable outsourcing partner, companies can redirect their resources and efforts towards their core business functions. This enhanced focus allows companies to improve overall productivity, innovation, and customer satisfaction.

Selecting the Right Outsourcing Partner

While the benefits of outsourcing cable assembly are undeniable, it is crucial to choose the right partner to ensure a successful collaboration. Consider the following factors when selecting an outsourcing partner:

Factors to Consider When Choosing an Outsourcing Partner

- Expertise and Experience: Ensure that the outsourcing partner has a proven track record in cable assembly, with expertise in your specific industry.

- Quality Assurance and Certifications: Look for certifications and quality assurance processes that the outsourcing partner adheres to, such as ISO standards.

- Scalability and Flexibility: Verify the outsourcing partner’s ability to scale production according to your needs and accommodate future growth.

- Proximity and Communication: Consider the geographical location of the outsourcing partner and assess their communication channels to ensure effective collaboration.

- Cost Considerations: While cost savings are a significant factor, make sure to balance it with the outsourcing partner’s capabilities and overall value proposition.

The Importance of Quality Assurance in Outsourcing

Quality assurance is vital when outsourcing cable assembly. Ensure that your outsourcing partner follows stringent quality control measures throughout the assembly process. Regular inspections and audits can help maintain consistency and conformity to specifications, ultimately safeguarding the quality of your product.

Potential Risks and How to Mitigate Them

Although outsourcing cable assembly presents numerous advantages, it is essential to be aware of potential risks and implement effective risk management strategies.

- Intellectual Property Protection: Ensure that proper confidentiality agreements are in place to protect your proprietary information.

- Supply Chain Disruptions: Evaluate your outsourcing partner’s supply chain management practices and diversify your supplier base to mitigate potential disruptions.

- Communication and Language Barriers: Establish clear and comprehensive communication channels to avoid misunderstandings and cultural differences.

- Quality Control Issues: Implement regular quality control audits and inspections to ensure the highest level of product quality.

- Long-Term Strategic Alignment: Choose an outsourcing partner that aligns with your long-term goals and values, ensuring a mutually beneficial partnership.

Strategies for Risk Management in Outsourcing

- Establish Clear Contracts: Define the terms and expectations in a comprehensive contract that protects both parties’ interests.

- Regular Performance Reviews: Conduct regular performance evaluations to ensure that the outsourcing partner is meeting your quality and efficiency standards.

- Collaboration and Communication: Foster open and transparent communication channels to address any issues promptly and facilitate mutual understanding.

- Contingency Plans: Develop contingency plans to mitigate potential disruptions and ensure business continuity, even in challenging situations.

- Continuous Improvement: Encourage a culture of continuous improvement and innovation within the partnership to drive ongoing success and mutual growth.

Frequently Asked Questions (FAQs)

- Can outsourcing cable assembly really save my company money? Yes, outsourcing cable assembly can lead to significant cost savings for your company. By partnering with a specialized contract manufacturer, you can avoid capital expenditures on equipment and infrastructure, as well as reduce overhead costs associated with maintaining an in-house cable assembly department.

- Will outsourcing cable assembly compromise the quality of our products? No, outsourcing cable assembly does not have to compromise product quality. In fact, partnering with a reputable outsourcing provider who follows strict quality control measures can ensure that your products meet or exceed industry standards.

- How do I choose the right outsourcing partner for cable assembly? Choosing the right outsourcing partner requires careful consideration of factors such as expertise, experience, quality assurance processes, scalability, communication, and cost. Assessing these factors will help you find a partner that aligns with your specific needs and requirements.

- What steps can I take to protect my intellectual property when outsourcing? To protect your intellectual property, it is crucial to have well-defined contracts that include confidentiality agreements. Additionally, you can implement strict access controls and limit the sharing of sensitive information with only authorized individuals within the outsourcing partner’s organization.

- Can outsourcing cable assembly provide my company with a competitive advantage? Absolutely. Outsourcing cable assembly allows your company to leverage the expertise and specialized skills of contract manufacturers, enabling you to focus on your core business functions and gain a competitive edge in the market. This streamlined approach frees up resources and improves overall operational efficiency, ultimately enhancing your company’s competitive position.

As companies strive to streamline their cable assembly processes and improve efficiency, outsourcing has emerged as a game-changing solution. By understanding the basics of cable assembly, the advantages of outsourcing, and the strategies for selecting and managing outsourcing partnerships, businesses can tap into cost savings, access specialized skills, and drive long-term growth. Embracing the benefits of outsourcing cable assembly can lead to a more streamlined and competitive business operation in today’s dynamic marketplace.

Ready to harness the competitive edge that outsourcing your cable assembly can offer? Cornelius Electronics is your ideal partner in this journey. With over four decades of expertise in wiring harnesses, cable assemblies, box builds, and system integration, our UK-based team operates from an expansive 50,000 square foot facility, ensuring your needs are met with precision and care. Join the ranks of our satisfied partners and experience controlled, repeatable volumes of high-quality components tailored to your business needs. Get in touch with us today and take the first step towards a more streamlined and efficient future.