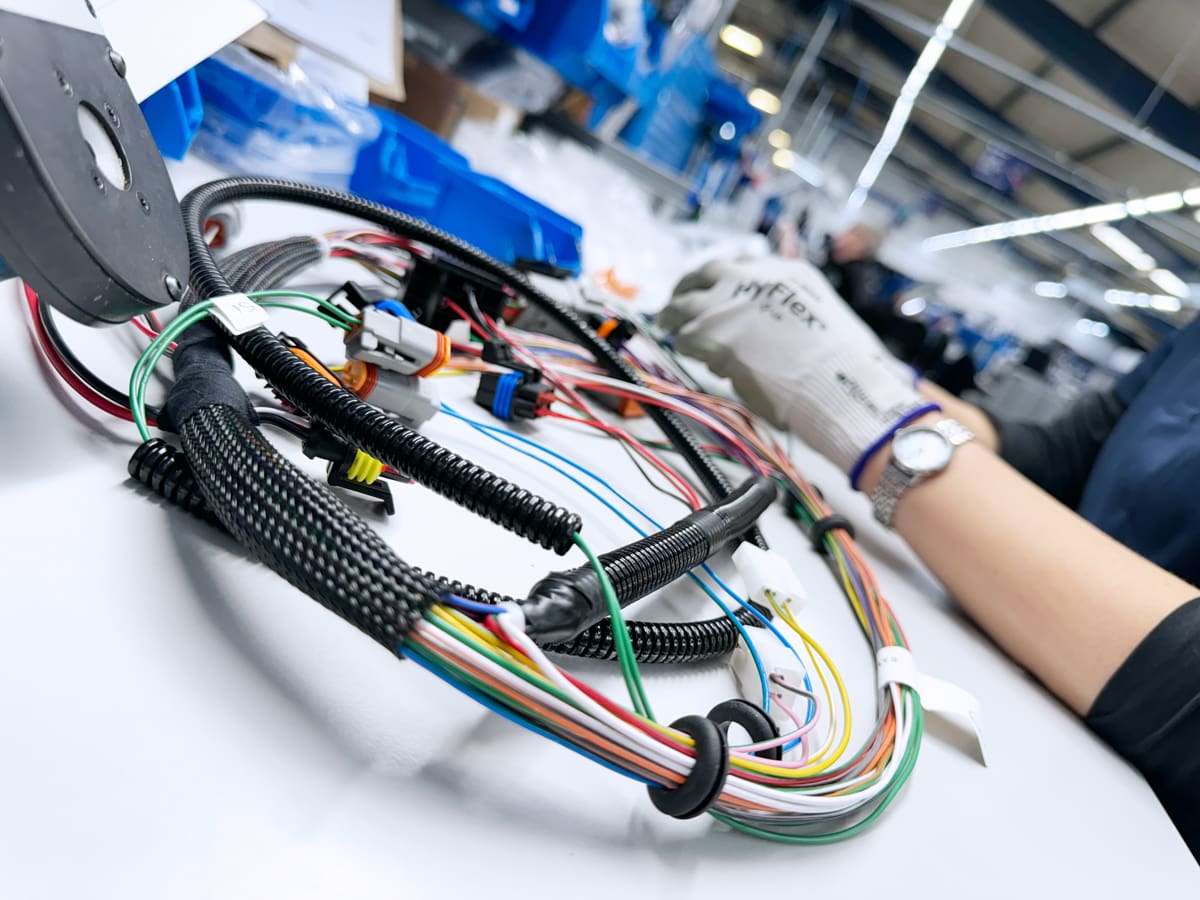

Welcome to our blog post on selecting the perfect cable assemblies and wiring harnesses for your project. Whether you are a seasoned professional or a beginner in the field, understanding the key challenges and making informed decisions can greatly impact the success of your project. In this article, we will provide you with top tips to help you master your project and choose the right cable assemblies and wiring harnesses.

1 – Understand your project requirements

Before diving into the selection process, it is crucial to have a clear understanding of your project requirements. Take the time to analyse the specifications and determine the specific needs of your project. Consider factors such as voltage, current, signal type, and data transfer rates. This will help you narrow down your options and ensure that the cable assemblies and wiring harnesses you choose are suitable for your project.

Consider the environment

The environment in which your cable assemblies and wiring harnesses will be installed plays a significant role in their performance and longevity. Different environments present unique challenges, such as extreme temperatures, moisture, chemicals, and vibrations. It is essential to assess the environmental conditions and select cable assemblies and wiring harnesses that are designed to withstand these challenges.

If your project involves outdoor installations, consider cables and harnesses with UV resistance and waterproof properties. For applications in harsh industrial environments, opt for cables and harnesses with ruggedized constructions and resistance to chemicals and abrasion. By considering the environment, you can ensure that your cable assemblies and wiring harnesses will provide reliable performance and durability.

2 – Choose the right materials

The materials used in cable assemblies and wiring harnesses can greatly impact their performance and reliability. It is important to choose materials that are suitable for your project requirements and the environment in which they will be used.

Wire and insulation materials

When selecting wire and insulation materials, consider factors such as conductivity, flexibility, and resistance to temperature and chemicals. Copper is a common choice for wire conductors due to its excellent conductivity. Insulation materials such as PVC, Teflon, and silicone offer different levels of flexibility and resistance to temperature and chemicals. Choose materials that meet the specific needs of your project.

Connector materials

Connectors play a crucial role in cable assemblies and wiring harnesses, as they provide the interface between different components. The materials used in connectors can impact their durability and performance. Common connector materials include plastic, metal, and rubber. Plastic connectors are lightweight and cost-effective, while metal connectors offer enhanced durability and conductivity. Rubber connectors provide flexibility and resistance to moisture. Consider the requirements of your project and choose connectors made from materials that best suit your needs.

3 – Ensure compatibility with components

Compatibility between cable assemblies, wiring harnesses, and components is essential for seamless integration and optimal performance. Before making your final selection, ensure that the cable assemblies and wiring harnesses are compatible with the components they will be connecting.

Connector types and pin configurations

Check the connector types and pin configurations of both the cable assemblies and the components. Ensure that they match and are compatible with each other. Mismatched connectors or pin configurations can lead to connectivity issues and performance problems.

Electrical and signal requirements

Consider the electrical and signal requirements of your components. Ensure that the cable assemblies and wiring harnesses can handle the voltage, current, and signal types required by your components. Failure to meet these requirements can result in unreliable connections and compromised performance.

4 – Plan for future expansion

When selecting cable assemblies and wiring harnesses, it is important to consider future expansion and scalability. Anticipate any potential changes or additions to your project and choose cable assemblies and wiring harnesses that can accommodate these future needs.

Allow for extra length

When determining the length of your cable assemblies and wiring harnesses, consider leaving some extra length for future flexibility. This will allow you to make adjustments or add components without the need for extensive rewiring or cable replacement.

Modularity and compatibility

Opt for cable assemblies and wiring harnesses that offer modularity and compatibility with a wide range of components. This will make it easier to expand or upgrade your project in the future without the need for significant modifications.

Finally – Test and validate before installation

Before installing your cable assemblies and wiring harnesses, it is crucial to test and validate their performance. This will help identify any potential issues or defects and ensure that they meet the required specifications.

Electrical testing

Perform electrical testing to verify the conductivity, insulation integrity, and signal quality of your cable assemblies and wiring harnesses. Use appropriate testing equipment and follow industry standards to ensure accurate results.

Environmental testing

Subject your cable assemblies and wiring harnesses to environmental testing to simulate the conditions they will be exposed to. This can include temperature cycling, humidity testing, vibration testing, and exposure to chemicals. Environmental testing will help identify any weaknesses or vulnerabilities in the materials and construction of your cable assemblies and wiring harnesses.

By following these top tips, you can master your project and select the perfect cable assemblies and wiring harnesses for your specific challenges. Understanding your project requirements, considering the environment, choosing the right materials, ensuring compatibility with components, planning for future expansion, and testing and validating before installation are all crucial steps in the selection process. Take the time to make informed decisions, and you will set yourself up for success.

Ready to tackle your project’s challenges with confidence? Partner with Cornelius Electronics, the UK’s trusted contract manufacturer for high-quality cable assemblies and wiring harnesses. With over 40 years of expertise and a state-of-the-art 50,000 square foot facility, our team of 250 trained operatives is dedicated to providing partnership-focused solutions tailored to your needs. For controlled, repeatable volumes of top-tier components, get in touch with Cornelius Electronics today and ensure your project’s success.