A well-designed wiring harness is essential for operational efficiency and safety, but selecting the right solution requires careful consideration.

Here’s how to ensure your wiring harness is both cost-effective and high-performing for your business needs.

What is a Wiring Harness?

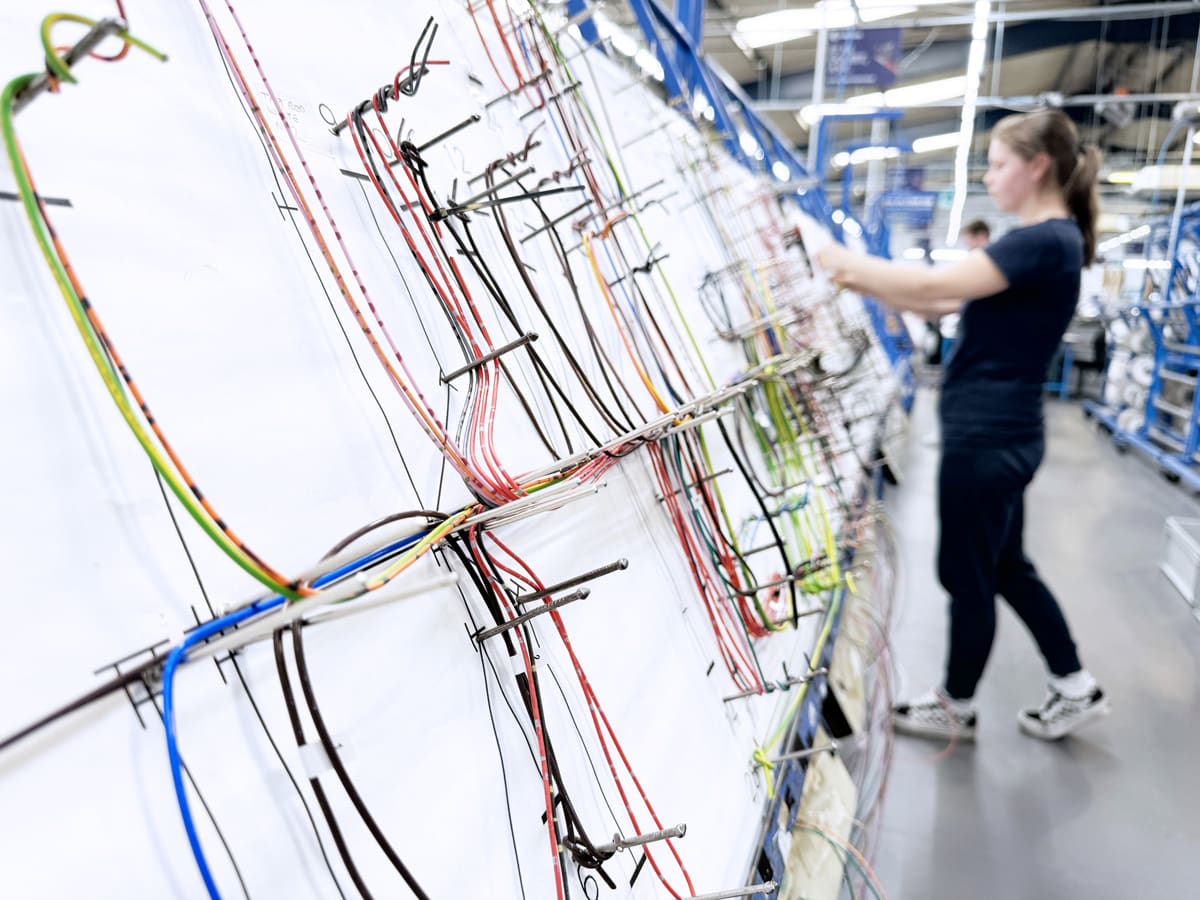

A wiring harness—also known as a cable harness or wire loom, is a collection of electrical wires and cables bundled together with connectors, terminals, and other components. Its primary function is to transmit electrical signals and power between different components within a system, such as a vehicle or electronic device. By organising and protecting the wires, a wiring harness simplifies installation, repair, and maintenance, reducing the risk of short circuits and improving overall system performance.

The role of a wiring harness in your business cannot be overstated. It ensures efficient and reliable transmission of electrical signals, enabling seamless communication between various components. A well-designed harness improves performance, durability, and safety, leading to increased productivity and customer satisfaction.

The Role of Wiring Harness in Your Business

A wiring harness provides a systematic and organised approach to connecting electrical components. By consolidating multiple wires into a single harness, it minimises the risk of errors during installation and enhances ease of maintenance and troubleshooting. Additionally, it acts as a protective barrier, shielding wires from environmental factors such as moisture, dust, and vibrations – common causes of system failures.

Moreover, a wiring harness improves overall safety. Proper insulation and grounding reduce the risk of electrical shock or fire hazards, which is especially critical in industries like automotive and aerospace, where safety regulations are stringent and non-compliance can have severe consequences

Benefits of a Well-Designed Wiring Harness

- Simplified Installation:

- Connectors and terminals are already integrated, saving time and reducing labour costs.

- Eliminates the need for manual connections and crimping, leading to faster assembly and fewer errors.

- Enhanced Reliability and Durability:

- Minimises risk of wire damage and short circuits.

- Promotes uninterrupted operation and reduces unplanned downtime, boosting productivity and customer satisfaction.

- Scalability:

- As your business grows, modifying or expanding your electrical system becomes simpler and more cost-effective.

- Easily add or replace components without extensive rewiring, minimising disruptions and costs.

Identifying Cost-Effective Solutions

While the importance of a wiring harness is clear, it’s vital to consider cost-effectiveness. Investing in the right harness yields significant long-term benefits, including cost savings and operational efficiency.

Key factors to consider:

- Assess Your Requirements:

- Determine necessary features and specifications (wire gauge, number of circuits, connector types, compatibility).

- Evaluate Quality and Reliability:

- Choose reputable manufacturers or suppliers who adhere to industry standards and certifications like (IPC/WHMA-A-620).

- Look for excellent performance, durability, and resistance to environmental factors.

- Balance Cost and Value:

- Avoid the cheapest options that may compromise quality.

- Consider long-term benefits and savings over upfront costs.

Affordable vs. Expensive: What’s the Difference?

Cost-effectiveness is not synonymous with cheapness. While an affordable harness may fit your budget, it may lack durability and compatibility, leading to frequent repairs or replacements. Conversely, an expensive harness may offer top-tier features, but if it exceeds your requirements, it’s an unnecessary expenditure. Strive for a balance between affordability and quality to ensure the best fit for your needs.

Implementing Wiring Harness Solutions in Your Business

Once you’ve identified the right solution, careful planning and execution are essential. Follow these steps for a smooth transition:

Transitioning to a New System

- Assess Your Current System:

- Identify bottlenecks, areas for improvement, and compatibility issues.

- Develop a Transition Plan:

- Outline steps for removing old harnesses, integrating new components, and testing the system.

- Train Your Staff:

- Ensure employees are trained to install, maintain, and troubleshoot the new system.

- Integrate Gradually:

- Minimise risk and disruption by phasing in the new system.

- Test and Validate:

- Conduct thorough functionality tests and address any issues promptly.

Maintenance Tips

To maximise performance and reliability, follow these maintenance tips:

- Regular Inspections:

- Check for wear, loose connections, or damage.

- Keep It Clean:

- Remove dust, grime, and corrosion from harnesses and connectors.

- Protect from Environmental Factors:

- Shield against moisture, extreme temperatures, and vibrations.

- Address Issues Promptly:

- Fix abnormalities immediately to prevent further damage.

- Stay Updated with Industry Standards:

- Keep abreast of standards and best practices to ensure compliance and up-to-date solutions.

Future Trends

The field of wiring harnesses is continuously evolving, driven by advancements in technology and industry demands. Staying updated with these trends can give your business a competitive edge and help you make informed decisions regarding your electrical system.

Technological Advancements

One of the most significant trends is the integration of smart technologies. Features such as sensors, diagnostic capabilities, and connectivity options enable real-time monitoring, predictive maintenance, and enhanced system control. By leveraging these advancements, businesses can optimise operations, reduce downtime, and improve overall efficiency

How to Stay Updated

Keeping up with the latest trends in wiring harness solutions requires continuous learning and engagement with industry resources. Here are some ways to stay updated:

- Attend conferences and seminars: Participate in industry events that focus on electrical systems, where you can gain insights into the latest technologies and best practices in wiring harness solutions.

- Join industry forums and communities: Engage with professionals and experts through online forums and communities dedicated to electrical systems. Share knowledge, ask questions, and stay informed on emerging trends.

- Subscribe to industry publications: Subscribe to reputable publications that cover electrical systems, wiring harness solutions, and related technologies. These publications often provide in-depth analysis, case studies, and updates on the latest trends.

- Collaborate with suppliers and manufacturers: Maintain a close relationship with your suppliers and manufacturers. They can provide valuable insights into emerging technologies and trends in wiring harness solutions.

- Invest in professional development: Encourage your employees to pursue professional development opportunities, such as courses or certifications in electrical system design and wiring harness solutions.

Conclusion: Maximising the Benefits

A cost-effective wiring harness solution is crucial for businesses to ensure the efficiency, reliability, and safety of their electrical systems. By understanding the importance of wiring harnesses, identifying cost-effective solutions, and implementing them with careful planning, businesses can optimise their operations and gain a competitive edge.

- Wiring harnesses are essential for efficient and reliable electrical systems in businesses.

- Well-designed wiring harnesses offer benefits such as simplified installation, improved system durability, and scalability.

- When choosing wiring harnesses, consider factors such as specific requirements, quality, and long-term cost-effectiveness.

- Implementing a new wiring harness system requires proper planning and gradual integration.

- Maintain your wiring harness system through regular inspections, cleaning, protection from environmental factors, and prompt issue resolution.

Final Thoughts on Wire Harnessing Systems for Businesses

In today’s rapidly advancing technological landscape, businesses need to stay informed about the latest trends in wiring harness solutions. By understanding the technological advancements and engaging with industry resources, businesses can make informed decisions and maximise the benefits of their wiring harness systems. As the backbone of your electrical system, a well-designed and cost-effective wiring harness solution is crucial for the success and sustained growth of your business.

Cornelius Electronics, a trusted UK-based partner with over 40 years of expertise. Our state-of-the-art 50,000 square foot facility and team of 250 trained operatives are dedicated to delivering high-quality wiring harness solutions tailored to your needs. Embrace the future with our partnership-focused approach and experience the difference in controlled, repeatable volumes of components.

Get in touch with us today to create a robust electrical system that propels your business forward.